Designed for high current control applications like smart meters, the FH29LA is a high performance electric latching relay. Featuring great switching capacity, low power consumption and extended life, the product uses magnetic retention mechanism to preserve the contact state following power failure. Certified by ISO9001 and ISO14001, it meets UC3 standard of IEC62052-31:2005.

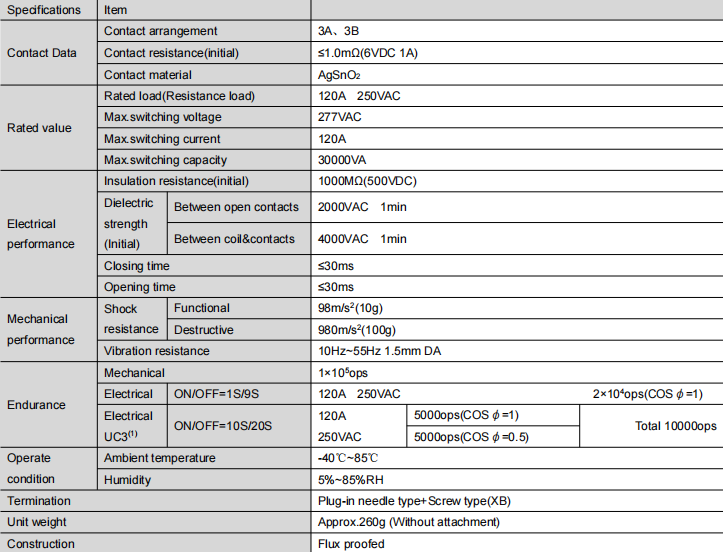

120A high current capacity, suitable for smart meters and other high-load applications.

Possesses a substantial switching capability of 30,000VA and functions dependably within a voltage spectrum of 250VAC to 277VAC.

Contact resistance is maintained at a low level (≤1.0mΩ) by utilizing AgSnO₂ contact material, which guarantees minimal loss and enhanced reliability.

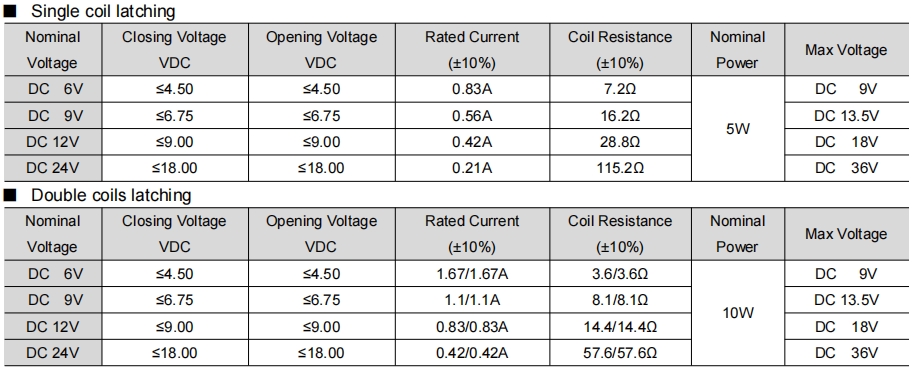

Single coil or dual coil available to meet different control needs.

Holding state after power failure, no need for continuous power supply, reducing system energy consumption.

Fast response, action time ≤30ms, suitable for high-precision control scenarios.

Electrical lifespan of up to 100,000 cycles (120A 250VAC) to satisfy long-term usage needs.

Superior insulation efficacy, 4KV between contact and coil, 2000VAC for 1 minute across open contact.

Robust anti-interference capability, appropriate for industrial frequency environments, ensuring reliable operation.

Operating temperature range -40℃~85℃, adapting to harsh environment.

Anti-vibration (10Hz~55Hz) and anti-shock (980m/s²), suitable for industrial and outdoor equipment.

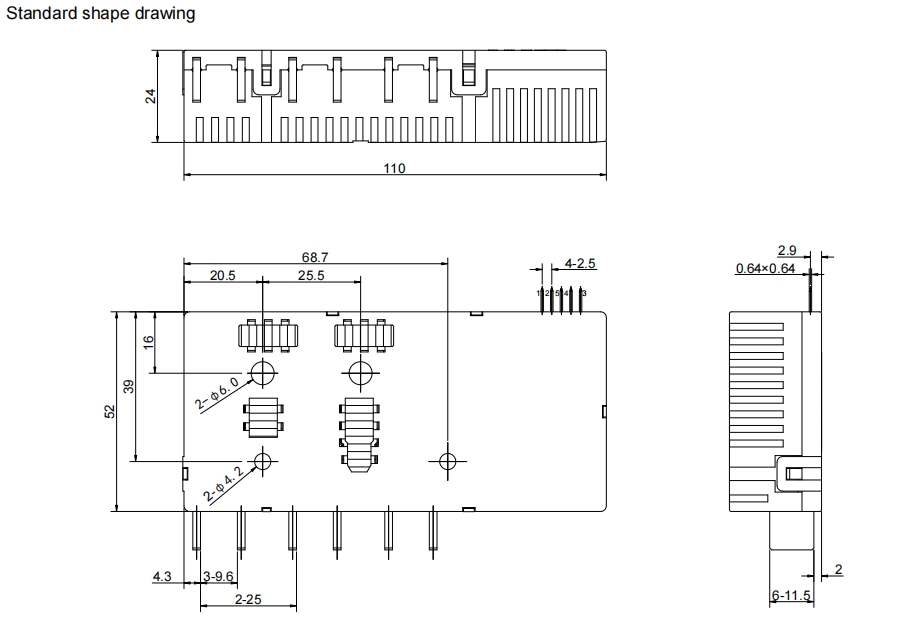

Compact size (110×52×24mm) for easy integration into PCB or automated production lines.

Supports customised accessories such as manganese copper shunts and transformers to meet different application requirements.

Smart meters (master switching, load control)

Power control systems (high current switching, power failure hold)

Industrial automation equipment (relay logic control)

New energy systems (photovoltaic, energy storage equipment)

The factory default is closed, before installation, you need to confirm that the contact state is in line with the demand.

The driving voltage is recommended to be 1~1.5 times of the rated value, pulse width ≥100ms, avoid long time energisation (>1min).

Avoid supplying power to ‘open’ and ‘closed’ coils at the same time to prevent false operation.

Load terminals are recommended to be spot welded, avoid reflow or wave soldering to prevent mechanical stress from affecting performance.

The FH29LA supports customised configurations (e.g. coil types, contact combinations, special accessories, etc.). For detailed specifications or technical support, please contact Zhejiang Fanhar Electronics Co.