Relay is a kind of electric control device, which is essentially an ‘automatic switch’ to control a larger current with a smaller current, and its basic structure is composed of sensing mechanism, intermediate mechanism and actuator. When the input quantity (e.g. voltage, current, temperature, etc.) reaches the set threshold, the relay can automatically connect or disconnect the controlled circuit to realise the automation control and protection function.

Electrical isolation capability: achieve electrical isolation between the control circuit and the controlled circuit through electromagnetic principle, protect the smart home control module from high voltage and high current impact.

Load Adaptation Wideness: Achieve safe opening and closing of high-current loads under low-level control signals, capable of integrating all kinds of household appliances.

Multi-device linkage basis: as an ‘execution terminal’, it is the physical basis for realising intelligent linkage between devices, such as temperature and humidity sensors controlling air conditioners or humidifiers.

Safety protection function: linkage with smoke detectors, gas alarms, etc., to automatically cut off the relevant circuits in dangerous situations.

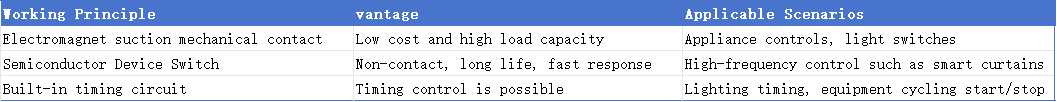

From the type of technology, the main applications of relays in the field of smart home include:

Intelligent lighting control: Relay modules are connected to the lighting circuit, and the switch, dimming and scenario mode switching of lights are controlled through mobile phone APP, voice assistant or automation scene. Multiple relay modules are often used to control lights in different areas, with light sensors to achieve automatic control.

Intelligent socket and appliance control: relays are embedded in intelligent sockets to achieve intelligent transformation of traditional home appliances. Users can remotely control the relay on and off to operate the equipment connected to the socket.

Electric curtains and doors and windows control: relays control the motor forward and reverse, to achieve the automatic management of electric curtains, intelligent doors and windows. It often cooperates with double-circuit relay or relay group to provide commutation function, and achieve intelligent effect through timing or light condition triggering.

Security equipment linkage control: relays are connected to the sensor network of the security system, triggering the alarm device, activating the camera recording and pushing the notification when abnormalities are detected.

Emergency cut-off in dangerous state: Relay is linked with smoke detector and gas leakage sensor to cut off the related circuit automatically to prevent the disaster from expanding.

Simulation of inhabited scenarios: The relay regularly controls the switching of lights, TVs and other equipment, and works with the intelligent host's preset scenario modes to simulate a situation where someone is at home and deter potential intruders.

Heating, ventilation and air conditioning (HVAC) control: relays are applied to the control circuits of air conditioning, floor heating, and fresh air systems, automatically adjusting the operating status of the equipment according to temperature and humidity sensor data.

Intelligent Shading System: Relays control electric blinds or sunshade motors, automatically adjusting the degree of shading according to light intensity, outdoor temperature and other parameters, combining sensors and meteorological data to achieve coordinated control.

Energy management and load scheduling: Relay realises intelligent load scheduling of home energy system, such as automatically switching on high-power devices during the low electricity price period, and automatically cutting off non-essential loads when electricity consumption is close to the capacity with smart meter and data analysis.

Load current and voltage specifications: select the relay capacity according to the power of the controlled equipment. Intelligent home load current varies greatly, such as LED lighting 0.5 - 2A, air conditioning compressor start 15 - 20A. Relay contact rating should be left a margin, the actual load current does not exceed 75% of the nominal value. Voltage in addition to considering the load operating voltage, but also look at the voltage rating, control of AC mains power, select the contact gap, there is a safety certification of the product.

Contact type and configuration: according to the circuit design need to choose normally open (NO), normally closed (NC) or changeover contact (CO) type relay. In smart home, NO type is used for lighting and socket control, and NO and NC contacts are needed for security system. Multi-contact group relay module is optional for multi-channel control scenarios, such as 4-channel and 8-channel all-in-one type, which saves space.

Control signal compatibility: Smart home controllers often provide 3.3V or 5V DC control signals, relay coil voltage needs to be matched. Low-power applications should pay attention to the suction voltage and holding voltage to ensure reliable operation when the power supply fluctuates. Some low-power relays are designed with magnetic retention and consume power only when switching states, which is suitable for battery-powered wireless smart devices.

Load type adaptation: resistive loads are friendly to relays; inductive loads are prone to high-voltage arcs when disconnected, requiring relays with large contact gaps or arc extinguishing designs; capacitive loads have large inrush currents at the moment of closure, requiring strong anti-melting and welding resistance of the relay contacts. For example, TE's T9G series relays, with contact materials optimised for HVAC compressor control, are able to withstand 6 - 8 times the instantaneous current during motor start-up.

Arc extinguishing and protection circuits: high power or inductive load circuits should be added protection components. Commonly used solutions include parallel RC absorption circuit, series diode current renewal, adding varistors and so on. Transistor-driven relay, coil ends in reverse parallel with a diode to prevent high-voltage breakdown of the drive tube when the shutdown.

Switching frequency considerations: frequent switching scenarios, such as intelligent dimming, motor PWM control, priority selection of solid-state relays or high-frequency electromagnetic relays. Ordinary electromagnetic relay mechanical life of about 10 ^ 5 times, solid state relay can be more than 10 ^ 8 times, but the cost is high, there is a conduction voltage drop. According to the actual switching frequency to do economic evaluation, lighting control choose high-quality electromagnetic relays, smart curtains, solid-state relays are more appropriate.

Temperature and humidity range: outdoor smart devices need to relay wide temperature work, such as -40 ℃ ~ 85 ℃; indoor cabinet products 0 ℃ ~ 60 ℃ can be. High humidity environment choose moisture-proof encapsulation or special coating relay, anti-contact oxidation. Relay modules for smart home controllers of Juying Electronics, with a working range of -20℃~60℃, meet most indoor needs.

Mechanical stress resistance: vibration or shock position, such as next to the motor of electric curtains, choose relays with good vibration resistance and anti-jitter design of contacts. Automotive grade relays can be used in harsh environments, such as TE automotive relay series, with good vibration resistance and sealing, high cost but high reliability.

Safety approvals and life expectancy: For critical applications, select products with UL, VDE, CE and other approvals. Life indicators include electrical life and mechanical life, high quality relay electrical life up to 10 ^ 5 times, smart home security, HVAC and other key systems should pay attention to these indicators, to prevent relay failure to system failure.

Transistor drive circuit: suitable for microcontroller to directly control the relay. Typical design contains NPN transistor, base current limit resistor and pull-down resistor. when GPIO outputs a high level, the transistor conducts and the relay is engaged; when it outputs a low level, the transistor cuts off and the relay is released. Key design parameters include base current and collector loop continuity diode.

Optocoupler Isolated Driver: Used for high security applications to electrically isolate the control signal from the relay coil. the GPIO is connected to the optocoupler input through a current limiting resistor, and the output drives a transistor or MOSFET to control the relay coil. This design prevents interference from the utility side and improves immunity to interference.

IC Driver: Suitable for multiple relay control system. Dedicated driver IC integrates multiple Darlington tubes and current-continuing diodes, and a single chip can drive multiple relays with compact layout and high reliability, but low flexibility.

ESP8266/ESP32 control programme: ESP series chips can directly or indirectly control relay modules via GPIO. Typical connection is GPIO → current limiting resistor → optocoupler input → transistor → relay coil. Through Wi-Fi connection, users can send control commands remotely, and the ESP chip parses and changes the GPIO state to operate the relay action. The open source firmware provides a mature relay control implementation, supports advanced features, and reduces development difficulties.

Arduino Platform Integration: Development boards such as Arduino Uno are commonly used for smart home prototyping, and their relay control is relatively simple, with digital output pins directly controlling relay coils through transistors or driver modules. Rich library resources and community support make it ideal for education and small smart home projects.

Commercial Smart Gateway Connectivity: Whole house smart systems use a dedicated gateway to control relay modules via wireless protocols. The relay module acts as an actuating terminal and forms a complete IoT system with sensors and controllers, representing the mainstream development of the smart home.

Power supply design and filtering: The power supply of the relay module should be stable and reliable, and filtering measures should be taken. Typical power supply design includes parallel connection of large-capacity electrolytic capacitors and small-capacity ceramic capacitors on the input side to filter out noise, use of LDO voltage regulator to provide stable voltage, and increase decoupling capacitors for each relay coil power supply. These measures can prevent the power supply fluctuations caused by relay operation from affecting the control circuit.

Contact protection circuit: relay contacts in the disconnection of inductive loads will produce an arc, commonly used protection methods include parallel RC absorption circuit, reverse parallel diode, the use of varistors. Perfect contact protection can extend the life of the relay and improve system reliability.

Wiring specification and isolation: strong and weak power lines should be routed separately to avoid parallel wiring; must be parallel to maintain the distance or use shielding measures. Relays are best installed in a separate area, physically isolated from the control circuit. For the control of high-voltage relays, ensure adequate creepage distance and electrical clearance, and use isolation boards or insulating materials to enhance safety if necessary.

As a key component connecting the digital world with the physical environment, the technological advancement of relays directly determines the capability and reliability of smart home systems. In the next five years, with the gradual realisation of the above trends, relays will evolve from an ‘invisible’ basic component to an active participant in the smart home ecosystem, bringing users a safer, more comfortable and energy-efficient living experience. For industry practitioners, to grasp these technical directions and layout product development in advance will occupy a favourable position in the fast-growing smart home market. The popularity of smart home will not eliminate the demand for relays, on the contrary, more complex and distributed home automation systems will require more high-performance, intelligent relay products.